Browse Our Collection

Get instant quotes that fit your budget perfectly.

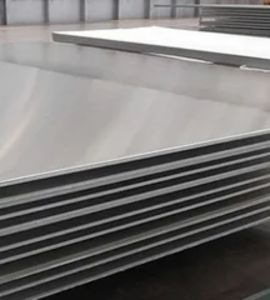

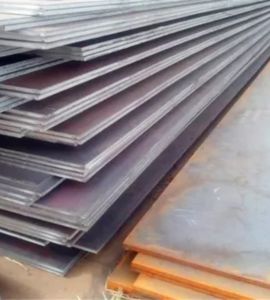

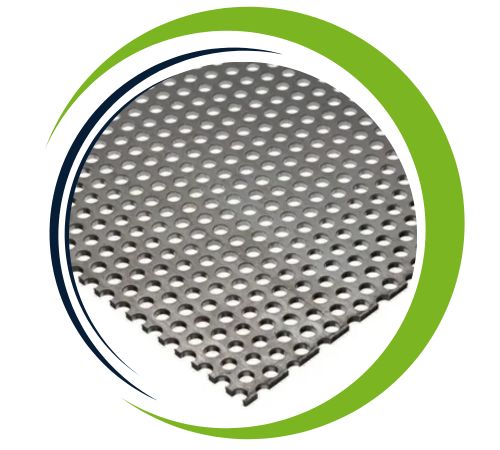

Based in Delhi, India, Daksh Sheets and Plates is a reputable producer and supplier of Inconel 690 Sheets and Plates. Our premium-grade Inconel 690 products are made to withstand high temperatures and extreme corrosion. Our Inconel 690 sheets and plates are designed to satisfy international quality standards and are renowned for their exceptional resistance to oxidising agents and thermal stability. Daksh provides services to a variety of industries, such as the nuclear, petrochemical, and power generation sectors, with an emphasis on accuracy, dependability, and prompt delivery. We are a dependable partner in both domestic and foreign markets thanks to our technical know-how and customer-focused philosophy.

About 58% nickel, 27–31% chromium, and 7-9% iron make up Inconel 690, a high-chromium nickel alloy. High-temperature corrosion, hot gases, and oxidising acids are all exceptionally resistant to this composition. With a tensile strength between 400 and 700 MPa and good creep resistance, Inconel 690 provides exceptional mechanical strength. Up to 1000°C, it retains its structural integrity at high temperatures. It is perfect for critical applications in nuclear and chemical processing environments because of its low carbon content, which guarantees resistance to stress-corrosion cracking and intergranular attack.

| Standards : | ASTM B168 / ASME SB168 |

| Dimensions : | ASTM, ASME, and API |

| Sheets Thickness : | Range from .008″ to .0125″ |

| Shims Thickness : | Range from .01″ to .0125″ |

| Plates Thickness : | Ranges from .0125″ to 5.00″ |

| Sheets/Plates Width : | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Sheets/Plates Length : | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Tempers : | Annealed, 1/4, 1/2 Hard, 3/4 Hard, Full Hard |

| Hardness : | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Value Added Service : | Cladding, Heat Treatment, Annealed, Pickling, Polish, Rolling, Cutting, Bending, Forging, Minor Fabrication Etc. |

| Element | Tensile Rm | Tensile Rm | R.p. 0.2% Yield | R.p. 0.2% Yield | Elongation (2” or 4D gl) |

| Inconel 690 | 86 ksi (min) | 590 MPa (min) | 35 ksi (min) | 240 MPa (min) | ≥30 % (min) |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 690 | 0.05 max | 0.5 max | 0.5 max | 0.015 max | 0.5 max | 7 – 11 | Remainder | 27 – 31 |

| Density | Electrical Resistivity | Modulus Elasticity | Thermal Expansion | Thermal Conductivity | Specific Heat (0-100°C) |

| 8.2 g/cm3 | 1.26 μohm/cm | 211 GPa | 14 mm/m/°C | 13.5 W.m -1.°K-1 | 450 J.kg-1.°K-1 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Daksh Sheets and Plates based in Hyderabad , India, is a leading supplier and stockist of high-quality metal products, including Sheets, Plates, Coils, Foils, Angles, Channels, Circles, and Slitting Coils, all offered with exceptional service and tailored to meet our customers specific requirements. With a focus on delivering superior products, we cater to a wide range of industries, providing reliable solutions for diverse applications. Our extensive inventory includes Known for our unique finishing techniques and commitment to quality. We are dedicated to ensuring customer satisfaction through dependable service and top-notch products.

Yes, we offer custom sizes for Inconel 690 Sheets and Plates to meet specific project needs. Our team at Daksh Sheets and Plates is dedicated to providing tailored solutions for all your requirements. For more details, contact us at sales@dakshsheetsandplates.co.in

| Tolerance over and under nominal thickness t (mm) | ||||||||||

| Width w (mm) | 2.54.56.08.010.012.516.020.025.030 | |||||||||

| w < 1200 | 0.20 | 0.23 | 0.30 | 0.32 | 0.35 | 0.80 | 0.80 | 0.80 | 1.0 | 1.4 |

| 1200< w <1500 | 0.20 | 0.25 | 0.30 | 0.35 | 0.38 | 0.80 | 0.80 | 0.90 | 1.0 | 1.4 |

| 1500< w <1800 | 0.20 | 0.28 | 0.32 | 0.38 | 0.40 | 0.80 | 0.80 | 0.90 | 1.1 | 1.5 |

| 1800< w <2100 | 0.20 | 0.30 | 0.36 | 0.40 | 0.45 | 0.80 | 0.80 | 0.90 | 1.1 | 1.5 |

| 2100< w <2400 | 0.80 | 0.80 | 0.80 | 0.80 | 0.80 | 0.90 | 1.0 | 1.1 | 1.5 | |

| 2400< w <2700 | 0.80 | 0.80 | 0.80 | 0.80 | 0.90 | 1.0 | 1.1 | 1.3 | 1.7 | |

| 2700< w <3000 | 0.80 | 0.90 | 1.0 | 1.0 | 1.0 | 1.1 | 1.3 | 1.4 | 1.8 | |

Industries that require exceptional resistance to heat and corrosion make extensive use of Inconel 690 Sheets and Plates. Heat exchanger tubing in nuclear power plants, feedwater heaters, and steam generators are some of the main uses. Because of its resistance to sulphur and oxidising agents, the alloy is also utilised in gas turbines, thermal oxidisers, and petrochemical processing. Because of its high chromium content, Inconel 690 can be used in environments that contain oxidising or nitric acids. It also provides long-lasting performance in harsh chemical and thermal environments, making it perfect for furnace components, superheaters, and structural elements exposed to high temperatures.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Discover high-quality products tailored to meet your unique needs and preferences.

Get instant quotes that fit your budget perfectly.

Hyderabad, India

Copyright 2024 Daksh Sheet and Plates. All rights reserved