Browse Our Collection

Get instant quotes that fit your budget perfectly.

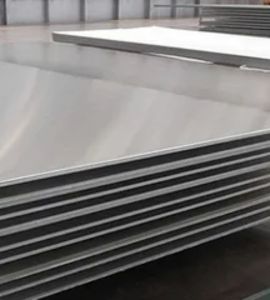

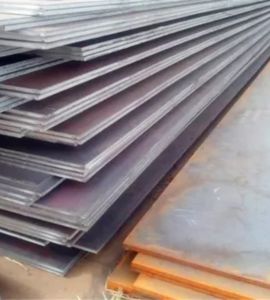

Based in Delhi, India, Daksh Sheets and Plates is a well-known producer and supplier of Inconel 718 Sheets and Plates. For demanding applications in the power generation, automotive, and aerospace industries, we offer high-performance nickel-based alloy solutions. Even at high temperatures and pressures, Inconel 718 is renowned for its exceptional strength, resistance to corrosion, and weldability. Daksh provides precisely engineered sheets and plates that satisfy both client requirements and global standards. We are a reliable supplier of Inconel 718 in India and the international industrial markets because of our dedication to quality, prompt delivery, and technical support.

Iron, niobium, and molybdenum are present in considerable amounts in Inconel 718, a precipitation-hardenable nickel-chromium alloy, with smaller amounts of titanium and aluminium. It usually contains 2.8–3.3% molybdenum, 4.75–5.5% niobium, 17–21% chromium, and 50–55% nickel. At temperatures as high as 700°C, Inconel 718 exhibits exceptional fatigue strength, outstanding creep resistance, and high tensile strength (up to 1240 MPa). The alloy is perfect for extremely demanding mechanical and environmental conditions because it retains good weldability and corrosion resistance, particularly against chloride and sulphide stress cracking.

| Specification | ASTM B670 UNS N07718, ASME SB670 |

|---|---|

| Sizes | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 0.1mm to 100 mm Thk |

| Width | 10-2500mm |

| Length | 2m, 2.44m, 3m, or as required |

| ASTM | ASTM B670 |

| AMS | AMS 5596 |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Stock in form of | Alloy 718 Plate, Sheet, Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Clad Plate, Rolling Sheet, Flat Sheet, Rolling Plate, Flat Shim, Blank (Circle), hot rolled, cold rolled, annealed, soft annealed, descaled, sheared, tread plate, Checker Plate |

| Material | JIS: N0, N2, N1, NW2200, NW2201, NW4400, NW5500, NW7182, etc DIN:H-Ni99.96, H-Ni99.95, H-Ni99.92, H-Ni99.90, H-Ni99.5, H-Ni99, etc |

| Why choose Superior Steel Overseas |

|

| Inconel 718 profiling | To provide a full profiling service we use numerous profiling methods including:

|

| Specialized in |

|

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 718 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 482 | 45 % |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015max | 0.30 max | – | 50.00 – 55.00 | 17.00 – 21.00 |

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Inconel 718 | 2.4668 | N07718 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Daksh Sheets and Plates based in Hyderabad , India, is a leading supplier and stockist of high-quality metal products, including Sheets, Plates, Coils, Foils, Angles, Channels, Circles, and Slitting Coils, all offered with exceptional service and tailored to meet our customers specific requirements. With a focus on delivering superior products, we cater to a wide range of industries, providing reliable solutions for diverse applications. Our extensive inventory includes Known for our unique finishing techniques and commitment to quality. We are dedicated to ensuring customer satisfaction through dependable service and top-notch products.

Yes, we offer custom sizes for Inconel 718 Sheets and Plates to meet specific project needs. Our team at Daksh Sheets and Plates is dedicated to providing tailored solutions for all your requirements. For more details, contact us at sales@dakshsheetsandplates.co.in

| Inconel 718 Plate Metric Dimensions | ||

|---|---|---|

| Surface finish | Thickness (mm) | Width (mm) |

| 2B – Cold rolled, heat treated, pickled, skin passed | 0.25–8.0 | max. 2032 |

| 2D – Cold rolled, heat treated, pickled | 0.4–6.35 | max. 1524 |

| 2E – Cold rolled, heat treated, mechanically descaled | 0.4–8.0 | max. 2032 |

| 2R – Cold rolled, bright annealed | 0.25–3.5 | max. 1524 |

| 2H – Work hardened | 0.4–6.35 | max. 1524 |

| Polished, brushed | 0.5–4.0 | max. 1524 |

| Thickness | Plate Weight per Unit Area | Density |

| 3/16 inches | 0.06000 lbs/in²42.184176 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1/4 inches | 0.08 lbs/in²56.245568 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3/8 inches | 0.121 lbs/in²85.0714216 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1/2 inches | 0.161 lbs/in²113.1942056 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 5/8 inches | 0.196 lbs/in²137.8016416 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3/4 inches | 0.235 lbs/in²165.221356 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 7/8 inches | 0.274 lbs/in²192.6410704 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 inches | 0.313 lbs/in²220.0607848 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 1/4 inches | 0.391 lbs/in²274.9002136 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 1/2 inches | 0.47 lbs/in²330.442712 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 3/4 inches | 0.549 lbs/in²385.9852104 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 inches | 0.627 lbs/in²440.8246392 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 1/4 inches | 0.705 lbs/in²495.664068 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 1/2 inches | 0.784 lbs/in²551.2065664 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 3/4 inches | 0.862 lbs/in²606.0459952 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3 inches | 0.941 lbs/in²661.5884936 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

Applications needing high strength, oxidation resistance, and corrosion protection at high temperatures make extensive use of Inconel 718 Sheets and Plates. They are frequently utilised in the aerospace industry for structural elements of aircraft, jet engine components, and turbine engines. Because of its strength and resilience to stress, Inconel 718 is also used in nuclear reactors, gas turbines, rocket motors, and cryogenic storage tanks. It is also utilised for parts like fasteners, valves, and pump parts in the chemical processing, oil and gas, and marine industries. It is perfect for harsh and mission-critical settings because of its adaptability and excellent performance under duress.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Discover high-quality products tailored to meet your unique needs and preferences.

Get instant quotes that fit your budget perfectly.

Hyderabad, India

Copyright 2024 Daksh Sheet and Plates. All rights reserved